System Introduction

System Introduction

Zhuzhou New Times Environmental Protection Technology Co.,Ltd. self-developed a suitable exhaust gas purification system for wood-based panel industry which includes Wet Electrostatic Precipitator system(WESP), Wet Scrubber System(WSS)and Dry Electrostatic Precipitator(ESP).

With the effective combination of wet scrubber, wet electrostatic precipitator and impeccable water circulation system, WESP can not only remove the particulate matters, but also eliminate VOCs, aerosol, blue haze, phenolic and aldehydes compounds in exhaust gas from dryer and press of wood-based panel industry. After the treatment, the concentration of particulate matter emission can be reduced to less than 10 mg/Nm3.

The wet scrubber system combines exhaust gas collection, wet cyclone separator and impeccable water circulation system, which can effectively remove particulate matter and part of soluble VOCs in press exhaust gas of wood-based panel industry.

ESP system effectively combines gas distribution system, high-voltage system, collector plate rapping system and collector, which can efficiently remove the dry dust generated by wood and biomass boiler and the dust removal efficiency is up to 99%.

WESP technological process introduction

WESP technological process introduction

Exhaust gas discharged from dryer and press is pre-moistened to the saturation point or dew temperature in the crude gas duct, and the large particles of pollutants are also removed in advance.

Phenol, formaldehyde and other water-soluble pollutants are separated in the wet absorber. At the same time, some concentrated tar, essential oil and some tar-like substances are also discharged into the absorbent tank with the spray water.

Aerosols, solid particles and blue haze are separated in a wet electrostatic precipitator. A field flushing system is set above the anode plate which flushing the anode plate 3-5 minutes at 3-12 hours interval. During the field flushing, the amount of flushing water is controlled by valve.

Passing through the electrostatic dust removal area, gas enters the high-voltage area(peak voltage: 100KV). A large amount of ozone O3 will be produced in the high-voltage area. Under the effect of strong oxidation of ozone O3, some hydrocarbons such as formaldehyde and phenol can be removed.

The clean gas is discharged after removing the attached water vapor by the gas's own rotation and the defogging effect of the droplet separator.

The wastewater contained with dust in the crude gas duct is separated from the solid and liquid by the drum screen and then enters the absorbent tank, and the filtered sludge enters the sludge dehydration system for deep dehydration.

The absorbent water is filtered through a back flush filter and then enters each spraying pipe, thereby reducing the risk of blocking the spraying system. The filtered concentrated liquid goes into the thick matter tank.

The concentrate water is dosed with chemical and then goes into the HPDF system. With the effect of compressed air, pollutants in the water produce microbubble aeration effect, that is, the formation of floating layer, and then the surface suspended impurities are removed by sludge scraper. Heavy impurities deposit on the bottom of flotation and collected by a sludge collecting device. The collected sludge goes through the sludge dehydration system for further treatment.

Wet scrubber system technological process introduction

Wet scrubber system technological process introduction

The exhaust gas from the continuous press is collected from the inlet and along the press by the suction hood, and is introduced into the main pipe system by the fan. Main pipe system is constructed from continuous press to the wet cyclone separator. The absorbent water is pumped into crude gas duct system, which can prevent the accumulation of sediment in the pipe as much as possible.

Special designed anti-blocking suction nozzles are set on the right and left side of gas outlet chamber of press to absorb the exhaust gas. These nozzles are connected with the collector. Meanwhile, the collector is also connected to the main pipe system. Absorbent water is injected into collector to ensure that no sediment will accumulated in the pipe.

The water in the collector is discharged into the middle tank below the press, and then pumped into the crude gas duct at the front of the wet cyclone separator.

The exhaust gas enters the wet cyclone separator through the main pipe. In order to reduce the amount of sludge and sediment, the water in the middle tank is pumped into the inlet of the wet cyclone separator, and flush the sediment to the bottom of the dust collector. The water discharged from the bottom of the wet cyclone separator is filtered by the drum screen and then discharged into the absorbent tank, and then pumped to the crude gas duct through the water pump for spraying.

After the exhaust gas mixed with water, some water soluble pollutants are absorbed by absorbent water. At the same time, hydrocarbon and particulate matter are also separated. After the treatment, cleaned gas is emitted from chimney to the sky.

System advantages

System advantages

High efficiency waste gas purification

High efficiency waste gas purification

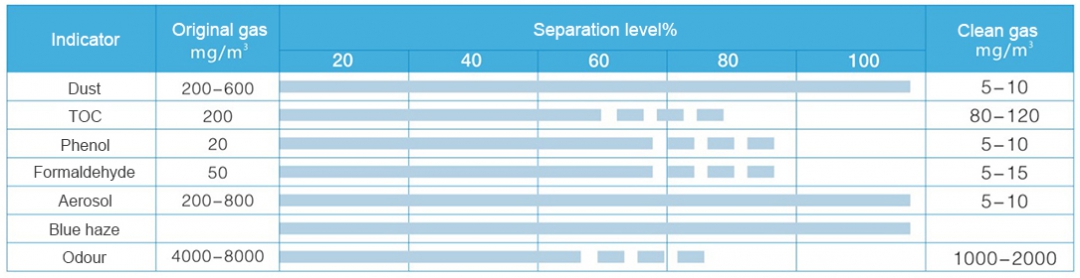

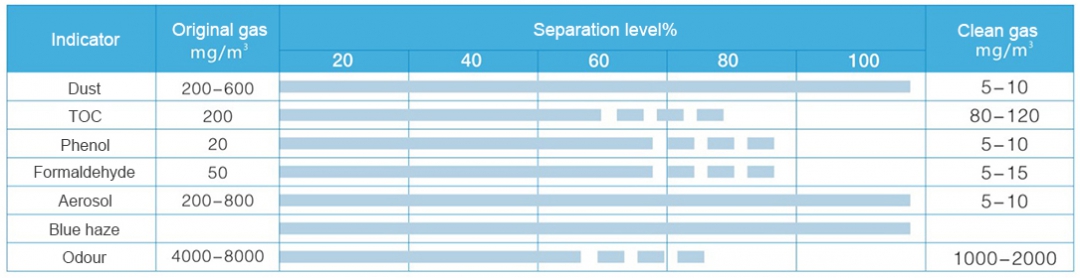

Refer to the table Information and Data for specific data.

High stability

High stability

The use of advanced technology, high quality equipment and a number of patented technology, to ensure the stability of the treatment effect.

High safety level

High safety level

Security configuration + perfect procedure control + emergency system to ensure the safety of personnel and system.

High benefit-cost ratio

High benefit-cost ratio

Under the same environmental benefit, the investment cost, operation cost and maintenance cost of the system are considered to be less.

Strong adaptability to inlet particle concentration

Strong adaptability to inlet particle concentration

Not only suitable for low concentration of particulate gas, but also suitable for high concentration of particulate gas.

Excellent materials and manufacturing technology

Excellent materials and manufacturing technology

Use anticorrosive materials, special surface treatment technology, improve corrosion resistance.

Efficient pretreatment process

Efficient pretreatment process

Cooling water is introduced into the crude gas duct to accelerate the condensation of particulate matter, so that most particulate matter can be separated efficiently in the crude gas duct.

Low wind pressure loss

Low wind pressure loss

The pressure loss of the main system is 350Pa, and the extra energy consumption increased by the system pressure loss is small.

High integration and covers a small area

High integration and covers a small area

The system integrates spraying pipe system, absorbent tank, electronic control system, HPDF system and other supporting equipment.

High modularization

High modularization

Modular design and manufacture, ensure equipment accuracy, reduce the workload of on site installation.

Energy saving

Energy saving

Combined with heat recycling system, discharged water amount can be reduced and large amount of heat energy can be recovered.

Optimized visibility

Optimized visibility

Selectively reduce steam emissions, improve visibility.

Information and data

Information and data

Technical parameters

System components

System components

Material: In the process of spraying, the absorbent water contacts with the exhaust gas will produce organic acids. In order to avoid the corrosion of organic acids, all the gas and water contact parts are made of stainless steel, and the accessories also use stainless steel or corrosion-resistant material.

Structure: In order to save the cost of production, transportation and assembly as much as possible, the wet electrostatic precipitator adopts modular structure to ensure the installation accuracy and reduce the production and installation workload on site.

Core: Through the primary filtration of the drum screen, large particulate matter such as clumped dispersed particles or coarse fibers are trapped, so as to avoid the obstruction of the absorbent water circulation process.

Scrubbers are composed of twisted and perforated sheets that provide strong resistance to blocking.

Wet electrostatic precipitator is designed as hexagonal honeycomb shape, which create a larger absorption area in a limited space.

A back flush filter specially designed for the system removes the finest solid particles from the absorbent water.

HPDF system with special structure can efficiently remove small suspended solids in absorbent water and maintain the stability of absorbent water operation index.

The heat recovery system can recover 1~25MW of usable heat energy and achieve a great return on investment.

WESP